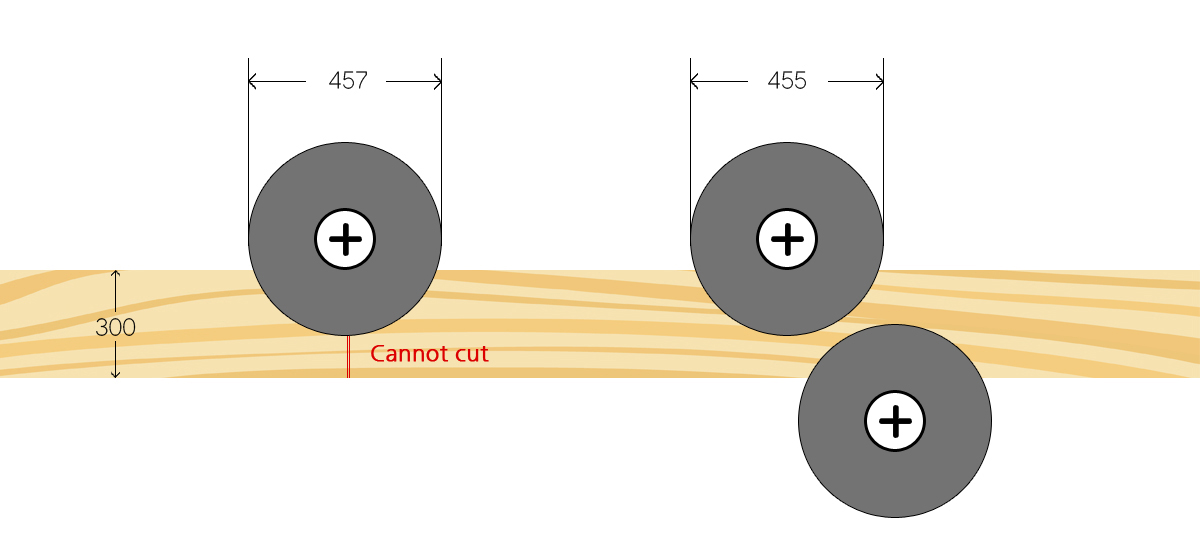

Comparison of effect between a single top and double tops

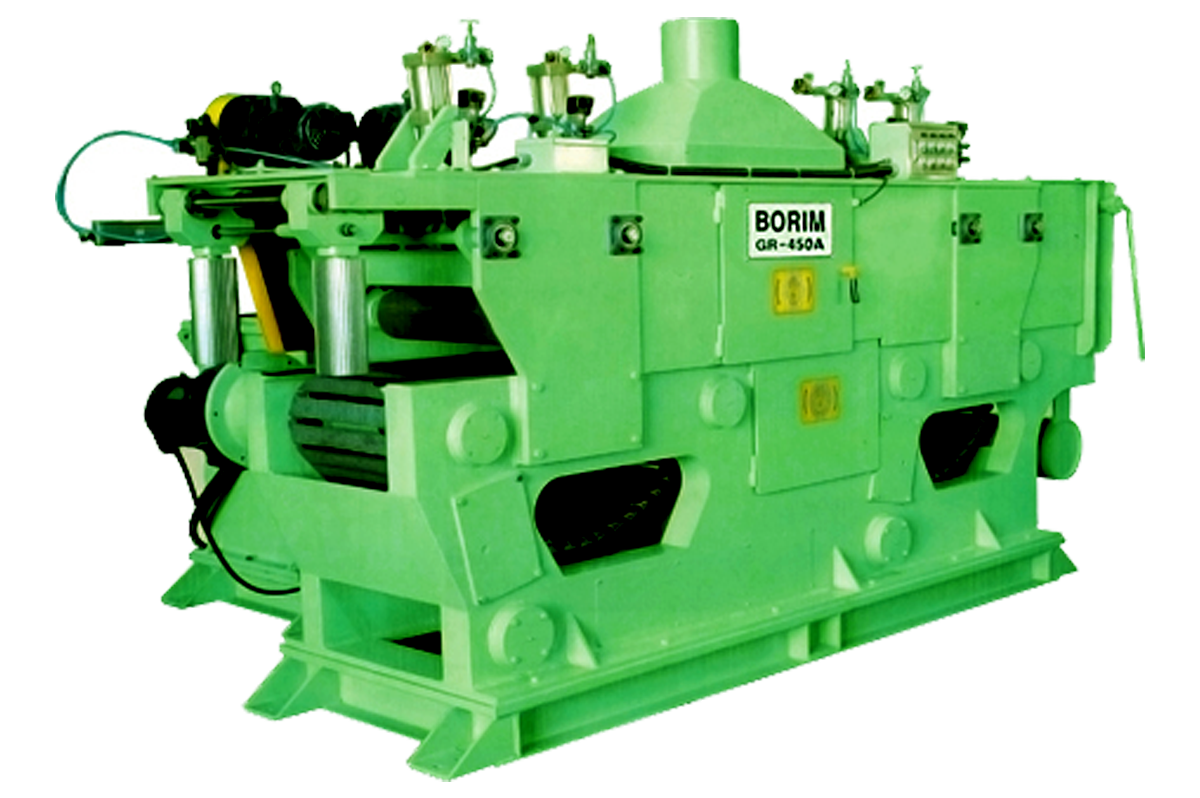

- It is a machine to cut the lumber that a single gang-rip saw cannot saw due to its considerable thickness. Therefore, it has an excellent durability and uses two axes (upper and lower) to cut wood as thick as 300mm at a single cut.

Because it uses a circular saw, it has output much smoother and cleaner than a band saw does. In addition, 2-speed caterpillar driving allows accurate cutting. And it minimizes and prevents from a fault from forming on the surface of the product after sawing work.